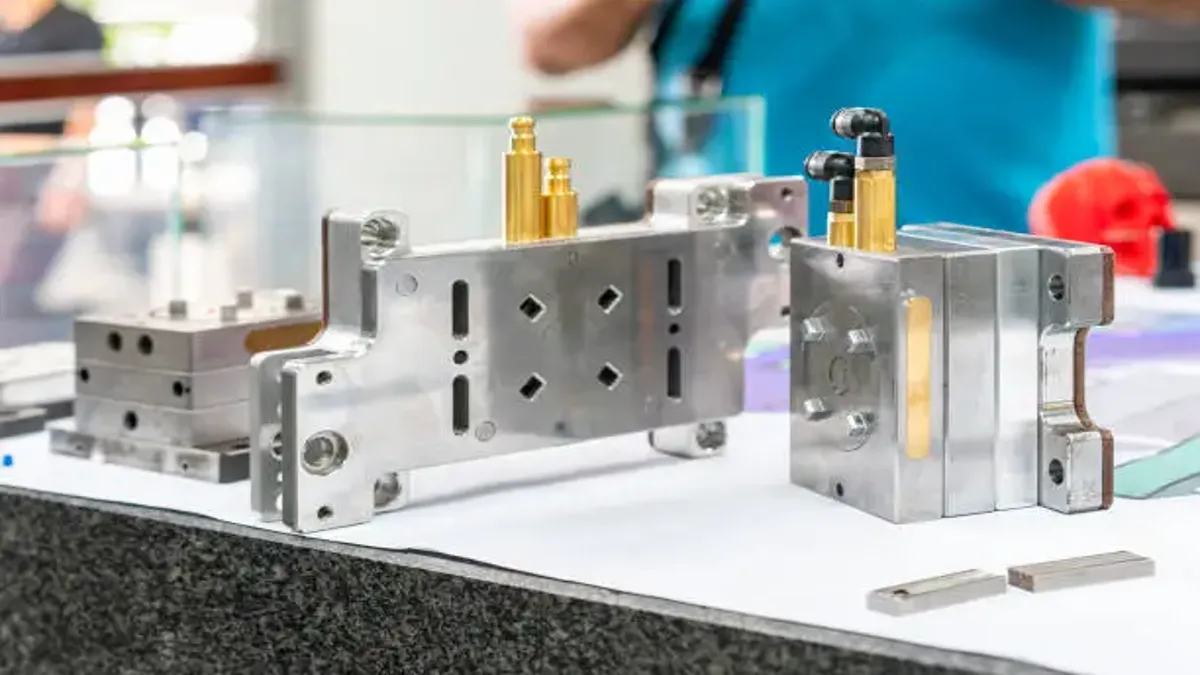

In modern manufacturing, few terms capture the blend of precision, innovation, and global relevance like Repmold. For those searching “What is Repmold, and why does it matter?” the answer lies in its role as a cornerstone in advanced mold-making technology. Repmold refers to specialized processes and systems for creating molds that shape countless products across industries—from automotive and medical devices to consumer goods and packaging. Within the first hundred words, it’s essential to establish clarity: Repmold is not just about making molds; it’s about redefining how products are designed, manufactured, and delivered with efficiency, sustainability, and unmatched accuracy.

The term encapsulates both a technological evolution and a cultural shift in manufacturing. Where once mold-making was confined to heavy industry and manual craftsmanship, Repmold’s represents a convergence of digital design, automation, and eco-friendly practices. It is a system designed for tomorrow’s industries, yet deeply rooted in the traditional craftsmanship of precision tooling.

The Evolution of Repmold

Mold-making has been central to human progress since the Bronze Age, where early molds shaped tools and ornaments. Repmold’s takes this ancient art into the 21st century, integrating CAD software, CNC machining, robotics, and eco-materials.

- Early Mold-Making: Labor-intensive, reliant on manual carving and casting.

- Industrial Revolution: Mechanization improved speed and consistency.

- Digital Era: CAD and 3D modeling transformed design.

- Repmold Era: Automation, sustainability, and global integration now define the field.

By merging digital modeling with sustainable practices, Repmold’s is more than evolution—it is reinvention.

Key Features of Repmold

- Precision Engineering: Tolerances within microns, vital for industries like aerospace and healthcare.

- Sustainable Practices: Incorporates recycled materials and energy-efficient processes.

- Global Scalability: Flexible production that supports small-batch prototypes and large-scale manufacturing.

- Digital Integration: Seamless use of CAD/CAM software with AI-driven error reduction.

- Versatility: Applications across automotive, electronics, packaging, construction, and medical devices.

These features ensure Repmold’s is not just a technical innovation but also an industrial philosophy that balances efficiency with responsibility.

Quotes Highlighting Repmold’s Importance

- “Repmold has elevated mold-making from an industrial necessity to a technological art form.” — Industrial Engineer

- “The precision of Repmold reflects the precision demanded by today’s global industries.” — Manufacturing Consultant

- “In an era of sustainability, Repmold bridges production with environmental responsibility.” — Environmental Analyst

- “Every product we hold in our hands, at some point, owes its shape to mold technology like Repmold.” — Design Researcher

Applications of Repmold

Repmold’s versatility makes it indispensable across industries:

- Automotive: Parts like dashboards, bumpers, and engine components.

- Medical Devices: Syringes, implants, and surgical tools.

- Consumer Goods: Packaging, electronics casings, and household items.

- Construction: Prefabricated panels, fittings, and fixtures.

- Aerospace: Lightweight, durable components for aircraft interiors.

By enabling both high-volume manufacturing and custom designs, Repmold’s reflects the demands of modern economies.

Table: Repmold vs Traditional Mold-Making

| Feature | Repmold | Traditional Mold-Making |

|---|---|---|

| Precision | Micron-level accuracy | Limited by manual constraints |

| Sustainability | Eco-materials and energy efficiency | Resource-heavy and less eco-aware |

| Speed | Automated, faster turnaround | Slower, labor-intensive |

| Flexibility | Supports both prototypes and mass runs | Often confined to large-scale runs |

| Cost Efficiency | Optimized with automation and digital tech | Higher due to manual processes |

Repmold and Sustainability

Sustainability is central to Repmold’s philosophy. Mold-making is resource-intensive, but Repmold’s introduces greener methods:

- Reduced waste through digital precision.

- Use of recycled or bio-based materials.

- Energy-efficient production machinery.

- Extended mold life to minimize replacements.

By reducing environmental footprints, Repmold’s aligns with global climate goals while maintaining industrial competitiveness.

Repmold in the Digital Era

Technology is the backbone of Repmold’s. CAD/CAM integration ensures flawless mold design, while AI-driven algorithms detect errors before production begins. CNC machines achieve the necessary accuracy, while automation accelerates production.

Digital twins—virtual replicas of molds—allow testing before actual manufacturing, reducing costs and failures. This digital-first mindset makes Repmold’s the perfect example of Industry 4.0 in action.

Repmold and Global Manufacturing

Global supply chains demand efficiency and consistency. Repmold’s answers with molds that can be replicated across continents with uniform quality. Whether a car bumper is made in Europe or Asia, Repmold’s ensures the mold produces identical results.

For multinational corporations, this reliability reduces errors, builds trust, and creates cost savings. In smaller markets, Repmold’s supports startups and innovators with scalable mold solutions.

Challenges Facing Repmold

Despite its promise, Repmold’s faces certain hurdles:

- High Initial Costs: Investment in digital systems and automation is significant.

- Skilled Workforce: Requires engineers trained in both digital and traditional techniques.

- Global Competition: Competes with low-cost mold manufacturers worldwide.

- Technological Barriers: Smaller firms may struggle to adopt AI or CNC systems.

Yet, history shows that industries investing in innovation often reap long-term benefits. Repmold’s is no exception.

Table: Opportunities for Repmold Growth

| Opportunity | Impact on Industry |

|---|---|

| AI Integration | Reduces design errors, boosts efficiency |

| 3D Printing Synergy | Enables hybrid molds with faster prototyping |

| Renewable Materials | Strengthens sustainability credentials |

| Global Partnerships | Expands reach across continents |

| Workforce Training | Builds expertise and industrial resilience |

Repmold and Consumer Experience

While consumers rarely think about molds, their daily lives are shaped by them—literally. From the bottle of water they drink to the smartphone case they hold, Repmold’s ensures products are precise, durable, and affordable.

For businesses, this translates to brand trust. Companies using Repmold’s processes can advertise not only quality but also sustainable production, a powerful message in today’s consumer-driven market.

Educational Impact of Repmold

Repmold is also transforming education. Engineering programs increasingly incorporate mold-making modules with a focus on Repmold technologies. Students trained in CAD/CAM, sustainability, and automation are better prepared for global careers.

For countries seeking to boost manufacturing capacity, investing in Repmold education builds local expertise, reducing dependency on foreign technology.

Future of Repmold

The future of Repmold is intertwined with the future of manufacturing itself:

- 3D Printing Integration: Molds created faster and with fewer materials.

- Smart Molds: Sensors embedded to monitor wear and efficiency.

- Circular Economy: Molds designed for reusability and recyclability.

- Global Collaboration: Cross-border mold development teams sharing digital twins.

Repmold represents not only current precision but also future resilience.

Read: Albfilm24: Albania’s Digital Window into Cinema, Culture, and Storytelling

Conclusion

Repmold is not simply a keyword; it is a philosophy of modern manufacturing that blends tradition with cutting-edge technology. By addressing precision, sustainability, and scalability, it reflects the demands of an interconnected, environmentally conscious world.

From automotive to healthcare, Repmold is shaping industries while reducing waste and optimizing efficiency. Its digital-first approach ensures fewer errors and faster innovation cycles. While challenges exist, the opportunities are vast.