DTF ultravioleta, or ultraviolet direct-to-film printing, is rapidly emerging as one of the most promising advances in digital printing. Readers searching for this keyword often want to know what it is, how it differs from other printing methods, and what its implications are for businesses, sustainability, and consumer trends. Within the first hundred words, the essential answer is clear: DTF ultravioleta is a technology that uses ultraviolet (UV) curing inks combined with direct-to-film transfer processes, delivering sharper details, faster production, and more versatile applications compared to traditional techniques. It represents not only a technical innovation but also a redefinition of efficiency, creativity, and durability in the global printing industry. This article examines its foundations, technological aspects, business implications, and cultural relevance while offering fresh insights for professionals and consumers alike.

The Origins of DTF Ultravioleta

The DTF ultravioleta process is a hybrid innovation that blends two previously distinct methods: direct-to-film printing and ultraviolet curing. Traditional DTF gained popularity for allowing prints to transfer seamlessly onto a variety of fabrics without requiring pretreatment. UV printing, on the other hand, revolutionized signage and packaging by curing inks instantly under ultraviolet light, resulting in vivid colors and high durability. By merging these methods, DTF ultravioleta introduced a new level of speed and resilience. What once required multiple stages—pretreatment, drying, and curing—could now be streamlined into a precise and efficient workflow. This hybridization signals a larger trend in manufacturing, where convergence creates breakthroughs.

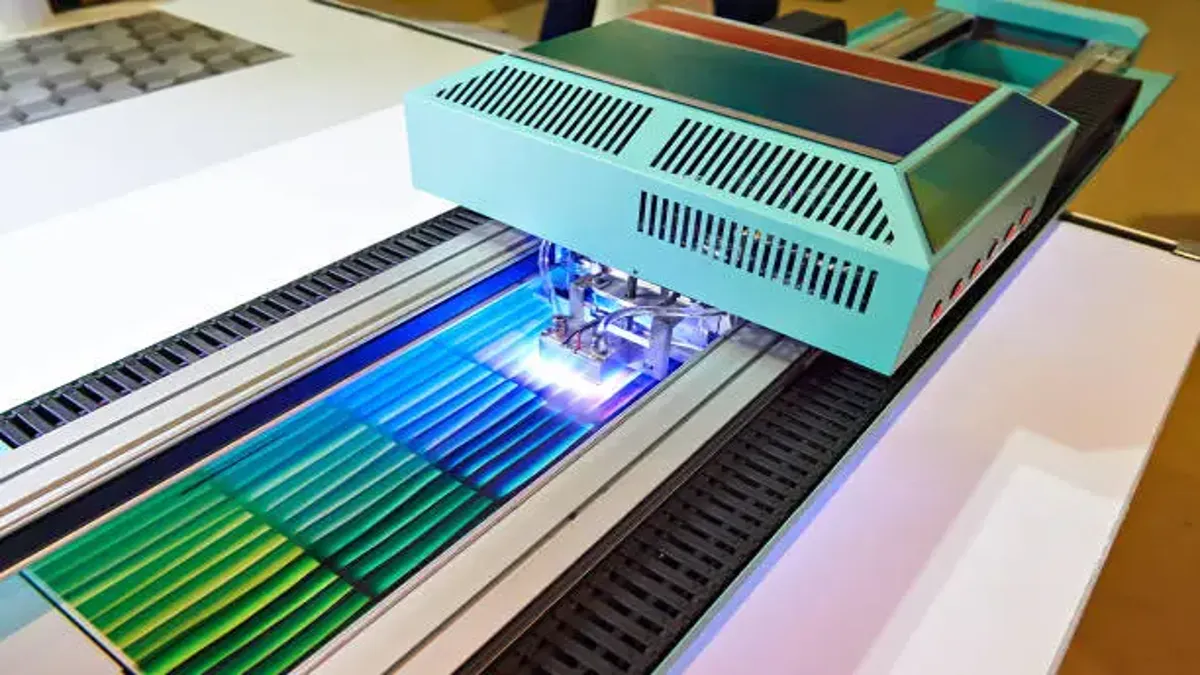

How the Technology Works

The DTF ultravioleta method operates through a simple yet advanced sequence. A design is first printed onto a special film using UV-curable inks. Instead of traditional drying, ultraviolet lamps instantly harden the ink, locking pigments in place with microscopic precision. Adhesive powders are then applied, and the cured film can be heat-pressed onto a wide range of substrates, from textiles to ceramics. Unlike older processes, which often suffered from fading or cracking, UV-cured layers maintain sharpness and elasticity. As one printing engineer remarked, “The brilliance of DTF ultravioleta is in its stability; it’s built for longevity without sacrificing color.”

Table: Comparison Between Printing Methods

| Feature | Traditional DTF | Sublimation | Screen Printing | DTF Ultravioleta |

|---|---|---|---|---|

| Pretreatment Needed | Sometimes | Yes | Often | No |

| Durability | Medium | High on polyester | Very high | Very high |

| Color Precision | Good | Vibrant but limited fabrics | Strong but layered | Exceptional |

| Speed | Moderate | Slow | Labor-intensive | Fast |

| Environmental Impact | Moderate | High water usage | Chemical-heavy | Lower energy, fewer solvents |

Advantages of DTF Ultravioleta

The reasons behind the growing attention to this technology are clear:

- Durability: UV-cured inks withstand washing, sunlight, and abrasion better than most alternatives.

- Versatility: Transfers can adhere to fabrics, glass, ceramics, wood, and even metals.

- Speed: Instant curing reduces production times, making same-day delivery possible.

- Eco-efficiency: UV inks emit fewer volatile organic compounds compared to solvent-based inks.

- Design flexibility: Crisp detail and gradient handling make it ideal for complex logos and photo-quality prints.

As one business owner summarized, “Switching to DTF ultravioleta wasn’t just about speed—it opened markets we hadn’t even imagined.”

Applications Across Industries

The practical applications of DTF ultravioleta extend beyond fashion printing. In the apparel sector, it allows small businesses to deliver custom designs without investing in large production runs. In interior design, the ability to transfer patterns onto ceramics or glass surfaces has created new possibilities for personalization. Packaging companies now explore DTF ultravioleta for prototypes and short-run products. Educational institutions and promotional businesses also benefit, using it for uniforms, awards, and marketing items. This expansion reflects a broader shift: personalization is no longer a luxury but an expectation.

Addressing Environmental Concerns

Sustainability is a recurring theme in modern industry, and printing technologies are under increasing scrutiny. While no process is impact-free, DTF ultravioleta reduces waste by minimizing water usage and eliminating many harsh chemicals. Because UV inks cure instantly, energy consumption is lower compared to dryers used in other methods. Still, challenges remain, particularly regarding recycling of films and disposal of UV lamps. Environmental researchers caution that “Innovation must not ignore responsibility; greener inputs are essential to balance progress with preservation.” Manufacturers are already responding with biodegradable films and energy-efficient curing units, signaling that eco-consciousness is becoming integral to future development.

The Economic Dimension

For businesses, the question is not only about innovation but also about viability. Initial investment in DTF ultravioleta equipment can be higher than conventional printers. However, operational costs often prove lower over time, with savings in labor, energy, and reduced waste. Small enterprises benefit from the ability to accept diversified orders, while larger companies gain efficiency in scaling operations. Analysts note that return on investment typically accelerates when businesses use the technology for customized or high-value items. As one financial consultant explained, “The cost equation tilts quickly when versatility meets consumer demand for uniqueness.”

Consumer Expectations in the Age of Personalization

Modern consumers increasingly demand personalization, rapid delivery, and sustainability. DTF ultravioleta aligns perfectly with these expectations, offering high-quality customization with reduced turnaround times. A sportswear buyer might order a personalized jersey and receive it within hours rather than days. A design studio can experiment with textures and materials without incurring prohibitive costs. Such responsiveness transforms consumer-business relationships, fostering loyalty and repeat business. In this sense, DTF ultravioleta is not just a technology but a cultural shift toward immediacy and individuality.

Table: Opportunities and Challenges

| Opportunities | Challenges |

|---|---|

| Expanding personalization markets | Higher upfront equipment cost |

| Growth in small-scale enterprises | Need for specialized training |

| Sustainable reputation | Recycling of films and inks |

| Diversification of applications | Regulatory compliance on UV inks |

| Enhanced consumer loyalty | Market saturation in fashion |

Challenges and Limitations

Despite its promise, DTF ultravioleta faces hurdles. Skilled operators are required to maintain quality, as improper curing can reduce durability. Upfront costs remain a barrier for smaller startups, and the learning curve may discourage rapid adoption. There is also competition from other emerging technologies such as digital textile printing with water-based inks or advanced sublimation systems. Moreover, as the technology gains popularity, market oversaturation is a risk, particularly in regions with low entry barriers. These realities remind businesses that innovation must be paired with strategy.

Regional Adoption and Global Outlook

In Europe, adoption is driven by sustainability directives and demand for eco-conscious printing. In Asia, particularly China and India, rapid adoption is tied to manufacturing competitiveness and cost advantages. North America emphasizes personalization and small-business integration, while Latin America explores the technology for regional fashion and cultural design markets. This uneven global spread reflects differing economic conditions but converges on the same outcome: DTF ultravioleta is positioned to become a cornerstone of printing innovation by 2030.

Expert Perspectives

Several voices offer perspective on its future. A designer stated, “What excites me is not only the speed but the creative freedom—no more limits on material or form.” A sustainability analyst countered, “The promise is real, but so is the need for circular solutions to handle waste responsibly.” Meanwhile, a manufacturer concluded, “DTF ultravioleta bridges industrial efficiency and artisanal creativity—it’s both scalable and personal.” Together, these insights highlight the tension between potential and responsibility.

Looking Ahead: DTF Ultravioleta by 2035

Forecasting the future of DTF ultravioleta suggests several possible paths. Optimistic projections envision a world where the technology replaces many older forms of printing due to efficiency and eco-performance. More moderate predictions suggest it will coexist with other processes, specializing in high-value or short-run applications. Either way, its role in personalization and design flexibility is unlikely to diminish. Long-term development will depend heavily on continued innovation in eco-friendly materials and regulatory harmonization.

Practical Tips for Businesses Considering Adoption

- Assess market demand: Start with customized, small-batch products where flexibility creates an advantage.

- Train staff properly: Quality depends on expertise in handling UV curing and film transfers.

- Prioritize eco-friendly materials: Choosing biodegradable films enhances reputation and reduces waste.

- Calculate ROI realistically: Factor in operational savings and potential new markets.

- Stay adaptive: Combine DTF ultravioleta with other printing solutions to remain competitive.

Conclusion

DTF ultravioleta stands at the intersection of technology, creativity, and sustainability. It is not merely a printing method but a cultural shift redefining expectations of speed, personalization, and responsibility. Its advantages—durability, versatility, eco-efficiency—position it as a transformative force across industries. Yet, challenges like upfront costs, training, and sustainability hurdles remain critical. The future will depend on how innovators and businesses balance efficiency with responsibility. As one industry observer aptly summarized, “DTF ultravioleta is less about replacing the old and more about inventing what comes next.”

FAQs

1. What is DTF ultravioleta printing?

DTF ultravioleta is a hybrid printing process that combines direct-to-film technology with ultraviolet curing for faster, durable results.

2. How does DTF ultravioleta differ from traditional DTF printing?

Unlike traditional DTF, UV curing eliminates drying time, improves color precision, and allows printing on more varied materials.

3. Is DTF ultravioleta environmentally friendly?

It reduces water and chemical use compared to older methods, though sustainable films and ink recycling remain ongoing challenges.

4. Which industries benefit most from DTF ultravioleta?

Fashion, packaging, interior design, and promotional products benefit significantly due to its speed, versatility, and customization capabilities.

5. What are the biggest challenges for adopting DTF ultravioleta?

High initial equipment costs, need for specialized training, and market competition are the main barriers to widespread adoption.